Tinned ọla kọpa wararabụ ihe igwe nwere akwa akwa tin n'elu eriri ọla kọpa. A na-ekewa usoro mmepụta nke eriri ọla kọpa tinned ụzọ atọ: tupu ọgwụgwọ, tin plating na post-ọgwụgwọ.

Dị ka ụzọ dị iche iche tin plating si dị, a pụrụ ikewa ya na electroplating na na-ekpo ọkụ itinye plating. Enwere ọdịiche dị n'etiti eriri ọla kọpa nwere agba agba na-ekpo ọkụtinned ọla kọpa wararan'ọtụtụ akụkụ.

I. Usoro usoro

1) Electroplating tinning: Ọ na-eji ụkpụrụ nke electrolysis na-ejieriri ọla kọpadị ka cathode na tin dị ka anode. N'ime ihe ngwọta electroplating nwere ion tin, a na-ebelata ion tin ma tinye ya n'elu akwa ọla kọpa iji mepụta oyi akwa tin-plated site na omume nke ugbu a.

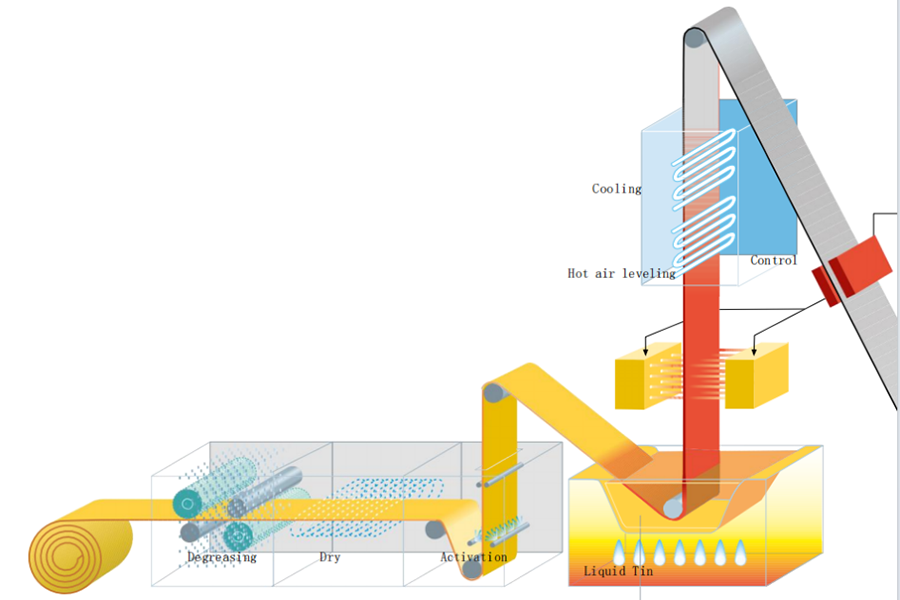

2) Tinning na-ekpo ọkụ: Ọ bụ iji mikpuo iheeriri ọla kọpan'ime mmiri mmiri gbazere agbaze. N'okpuru ọnọdụ okpomọkụ na oge ụfọdụ, mmiri mmiri tin na-emeghachi omume n'anụ ahụ na nke kemịkal na elu nke eriri ọla kọpa na-eme ka oyi akwa dị n'elu elu nke ọla kọpa.

II. Njirimara mkpuchi:

1) mkpuchi uniformity

A) Electroplating tinning: mkpuchi mkpuchi ahụ dị mma, ọ nwere ike ịmepụta akwa akwa akwa akwa na nke siri ike n'elu ala.eriri ọla kọpa. Karịsịa maka mpempe ọla kọpa nwere ụdị dị mgbagwoju anya na ebe na-enweghị isi, ọ nwekwara ike ikpuchi nke ọma, nke kwesịrị ekwesị maka ihe ngosi ngwa na ihe dị elu chọrọ maka mkpuchi mkpuchi.

B) Tinning na-ekpo ọkụ: Ịdị n'otu mkpuchi ahụ adịghị mma, na ọkpụrụkpụ mkpuchi na-enweghị isi nwere ike ime na nkuku na n'ọnụ ọnụ.eriri ọla kọpa. Otú ọ dị, maka oge ụfọdụ ebe ihe ndị a chọrọ maka mkpuchi mkpuchi na-adịghị mma, mmetụta dị ntakịrị.

2) ọkpụrụkpụ mkpuchi:

A) Electroplating tinning: Ihe mkpuchi mkpuchi dị ntakịrị, n'ozuzu n'etiti microns ole na ole na iri iri nke micron, enwere ike ịchịkwa ya nke ọma dịka mkpa dị iche iche si dị.

B) Tinning na-ekpo ọkụ: ọkpụrụkpụ mkpuchi na-abụkarị oke, n'ozuzu n'etiti iri puku microns na narị microns, nke nwere ike inye nguzogide corrosion ka mma ma na-eyi nguzogide.ibe ọla kọpa, mana ọ nwere ike ọ gaghị adabara maka ụfọdụ ngwa nwere mmachi siri ike na ọkpụrụkpụ.

III. Mmepụta arụmọrụ

1) Electroplating tin plating: Usoro mmepụta dị mgbagwoju anya, na-achọ ọtụtụ usoro dịka ọgwụgwọ mbụ, electroplating, na post-ọgwụgwọ. Ọsọ mmepụta na-adị ngwa ngwa ma ọ dịghị adabara maka nnukwu mmepụta na mmepụta ihe dị elu. Otú ọ dị, maka ụfọdụ obere-ogbe na ahaziri mmepụta mkpa, electroplating tin plating nwere ezigbo mgbanwe.

2) Na-ekpo ọkụ tin plating: Usoro mmepụta dị mfe. Enwere ike ịmecha usoro ịtinye tin site na imikpueriri ọla kọpan'ime mmiri mmiri tin. Ngwa ngwa mmepụta na-adị ngwa ngwa ma nwee ike gboo mkpa nke mmepụta buru ibu.

IV. Ike njikọ:

1) Electroplating tin plating: The bonding ike n'etiti mkpuchi naeriri ọla kọpamkpụrụ dị ike. Nke a bụ n'ihi na ion tin na-etolite njikọ kemịkalụ na atom ndị dị n'elu eriri ọla kọpa n'okpuru ọrụ eletrik n'oge usoro electroplating, na-eme ka mkpuchi ahụ sie ike ịdapụ5.

2) Na-ekpo ọkụ na-ekpo ọkụ: Ike njikọ dị mma, ma n'ọnọdụ ụfọdụ, n'ihi mmeghachi omume mgbagwoju anya n'etiti mmiri mmiri tin na elu nkeeriri ọla kọpan'oge usoro ntinye ọkụ na-ekpo ọkụ, ụfọdụ obere pores ma ọ bụ ntụpọ nwere ike ịpụta, na-emetụta ike njikọ. Otú ọ dị, mgbe ọgwụgwọ gachara nke ọma, ike njikọ nke ikpo ọkụ tin plating nwekwara ike izute ihe a chọrọ nke ọtụtụ ngwa.

V. Nguzogide corrosion:

1) Electroplating tinning: N'ihi mkpuchi dị mkpa, nguzogide corrosion ya adịghị ike. Otú ọ dị, ọ bụrụ na a na-achịkwa usoro electroplating nke ọma ma na-eme usoro ọgwụgwọ kwesịrị ekwesị, dị ka passivation, na-eguzogide corrosion nke ihe ndị dị na ya.tinned ọla kọpa wararanwekwara ike imeziwanye

2) Hot-mikpu tinning: mkpuchi bụ thicker, nke nwere ike inye mma corrosion na-eguzogide nchebe makaeriri ọla kọpa. N'ọnọdụ gburugburu ebe obibi siri ike, dị ka ikuku na-ekpo ọkụ na gburugburu ikuku na-emebi emebi, uru nguzogide corrosion nke ikpo ọkụ na-ekpo ọkụ.tinned ọla kọpa wararaka putara ihe5.

VI. Ọnụ

1) Electroplating tinning: Ntinye ego akụrụngwa dị ntakịrị, mana n'ihi usoro nrụpụta dị mgbagwoju anya, ọ na-eri ọtụtụ ọkụ eletrik na reagents kemịkalụ, ma nwee nnukwu ihe achọrọ maka mpaghara mmepụta na ndị na-arụ ọrụ, yabụ ọnụahịa mmepụta dị oke elu.

2) Tinning na-ekpo ọkụ na-ekpo ọkụ: Ntinye ego akụrụngwa buru ibu, yana ọkụ ọkụ na akụrụngwa ndị ọzọ dị mkpa ka e wuo ya, mana usoro mmepụta ahụ dị mfe na oriri akụrụngwa dị ntakịrị, yabụ ọnụ ahịa otu ahụ nwere ike ịdị ntakịrị na nrụpụta buru ibu.

Ịhọrọ atinned ọla kọpa wararadabara adaba maka ọnọdụ ngwa gị chọrọ nleba anya zuru oke nke ọtụtụ ihe dị ka akụrụngwa eletriki, akụrụngwa akụrụngwa, nguzogide corrosion, usoro mmepụta, ọnụ ahịa na nchekwa gburugburu ebe obibi. Dị ka mkpa ụfọdụ si dị, tụọ uru na ọghọm nke akụkụ niile wee họrọ nke kacha adabaratinned ọla kọpa wararaiji hụ na arụmọrụ na ịdị mma nke ngwaahịa ahụ.

Oge nzipu: Sep-18-2024