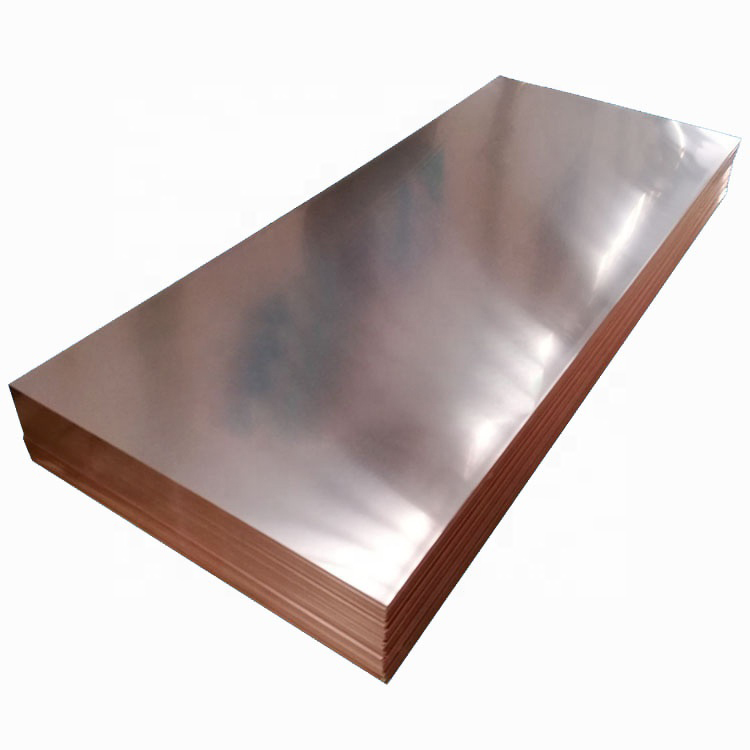

Phosphor Bronze

Bronze phosphor, ma ọ bụ tin bronze, bụ ọla ọla nke nwere ngwakọta ọla kọpa nwere tin 0.5-11% na 0.01-0.35% phosphorous.

A na-eji ọla kọpa phosphor eme ihe maka ngwaahịa eletriki n'ihi na ha nwere àgwà mmiri na-enweghị atụ, ike ọgwụgwụ dị elu, ọdịdị dị mma, yana nnukwu nguzogide corrosion. Mgbakwunye tin na-abawanye nguzogide corrosion na ike nke alloy. The phosphor na-eme ka ihe mgbochi na-eyi na nkwụsị nke alloy. Ihe ndị ọzọ na-agụnye ụda na-eguzogide corrosion, diaphragms, mmiri mmiri mmiri, bushes, bearings, shafts, gears, thrust washers, na valve akụkụ.

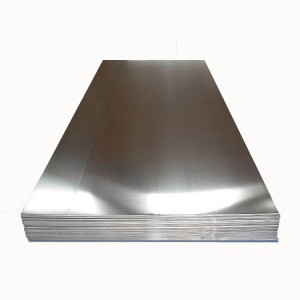

Tin Bronze

Tin bronze siri ike ma sie ike ma nwee ductility dị elu. Ngwakọta ihe ndị a na-enye ha ikike ibu ibu dị elu, ịdị mma na-eguzogide iyi, na ike iguzogide ịkụ ọkpọ.

Ọrụ bụ isi nke Tin bụ ime ka alloys ọla ndị a sie ike. Tin bronze siri ike ma sie ike ma nwee ductility dị elu. Ngwakọta ihe ndị a na-enye ha ikike ibu ibu dị elu, ịdị mma na-eguzogide iyi, na ike iguzogide ịkụ ọkpọ. A na-ahụ alloys ahụ maka nguzogide corrosion ha na mmiri mmiri na brines. Ngwa ụlọ ọrụ mmepụta ihe na-agụnye ihe nrụnye eji 550F, gia, bushes, bearings, impellers, na ọtụtụ ndị ọzọ.